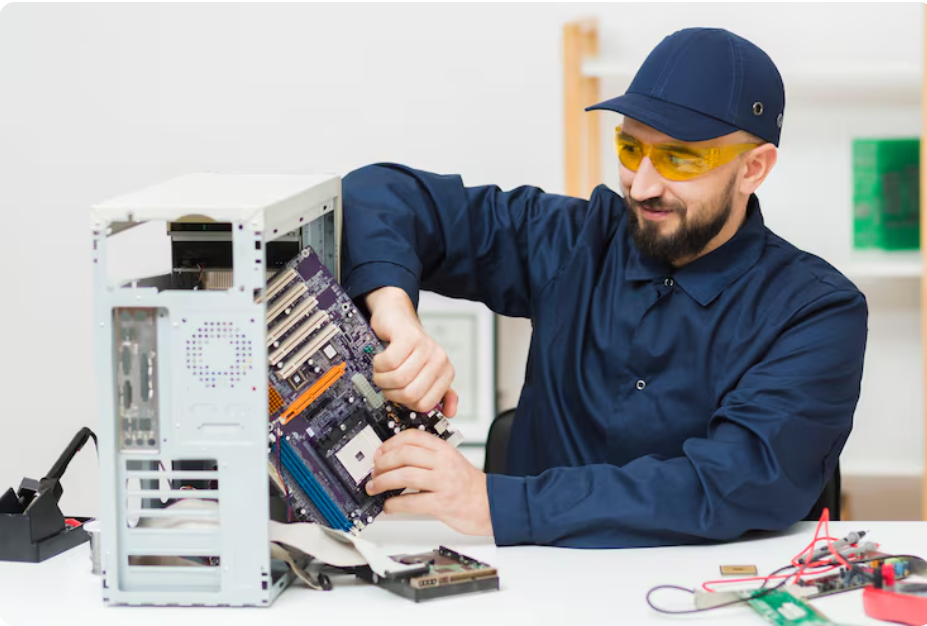

Modern maintenance and reliability practices now include the vibration tester as a crucial component for monitoring the health of equipment. As businesses depend on constant operations with little downtime, using a vibration tester machine can help find mechanical problems early on, before they get worse. These devices give technicians accurate information that helps them make quick decisions that help keep assets in good shape.

This article discusses the best reasons to use vibration testers when checking equipment and how they can help improve safety, performance, and cost-effectiveness.

How Vibration Testers Improve Equipment Monitoring

As the need for predictive maintenance and condition monitoring has grown, so has the importance of vibration testing. Technicians can figure out how well a machine is working without taking parts apart or stopping production by measuring the levels and patterns of vibration.

Vibration testers deliver real-time information that helps with preventative maintenance plans, which in turn lowers the number of unexpected failures. The following sections discuss seven valuable reasons to utilize vibration testers for monitoring equipment.

Detect Mechanical Imbalances Early

In rotating machinery, mechanical imbalance is a common problem and one of the main reasons why things break. By picking up on strange vibration patterns, a vibration tester lets technicians find imbalances early on. If you catch these problems early, you can keep bearings, shafts, and other parts from getting damaged. Fixing imbalances quickly makes sure that everything runs more smoothly and puts less stress on systems that are connected. This means that equipment lasts longer and needs fewer emergency repairs.

As mentioned in this article, you can improve this imbalance by using the right vibration tester for monitoring. Verify your requirements and accurately test the results without compromising the quality of the manufactured product.

Identify Bearing and Gear Faults

Bearings and gears are often the first components to show signs of wear in industrial machinery. A vibration tester machine detects subtle changes in vibration frequencies that indicate early-stage bearing defects or gear mesh irregularities. This data is invaluable for scheduling maintenance before these issues lead to full-scale breakdowns. By replacing or repairing parts in time, organizations can avoid production losses and maintain system reliability.

Improve Predictive Maintenance Efficiency

Predictive maintenance relies heavily on accurate and timely data. Vibration testers provide consistent monitoring, allowing teams to track trends and pinpoint deviations from normal operation. Rather than relying on routine time-based inspections, predictive strategies based on vibration analysis help extend maintenance intervals and reduce unnecessary downtime. This approach increases maintenance efficiency and allows resources to be focused where they are most needed.

Reduce Downtime and Production Interruptions

Unexpected equipment failures lead to costly production interruptions. With a vibration tester machine in place, potential issues can be identified before they cause unscheduled downtime. Real-time vibration analysis gives maintenance teams the time to plan interventions during scheduled shutdowns or low-production periods. This planning minimizes disruptions and keeps operations running smoothly, which is especially critical in high-output environments like manufacturing or processing plants.

Enhance Safety in Equipment Operation

Faulty equipment can pose serious safety risks to personnel. A vibration tester helps mitigate these risks by uncovering hidden faults before they become hazardous. High vibration levels may signal misalignment, loose parts, or failing components that could lead to mechanical breakdown or accidents. By monitoring these signs, maintenance teams can take corrective action quickly, creating a safer working environment and protecting both staff and infrastructure.

Support Long-Term Asset Health

Properly monitoring equipment is important for getting the most out of your investment and making assets last longer. By testing machines for vibrations on a regular basis, we can learn more about how they work over time. This information helps with long-term planning and deciding how to spend money on maintenance for assets that are wearing out or breaking down. A vibration tester machine is more than just a tool for finding problems; it’s part of a plan to keep important equipment healthy and make it last longer.

Use Data to Make Maintenance Decisions

One of the greatest strengths of a vibration tester is its ability to provide objective, data-driven insight. Maintenance managers can rely on vibration readings to guide decisions about repairs, replacements, or upgrades. Over time, vibration test data builds a historical record that supports better forecasting and equipment lifecycle planning. This information leads to more informed decisions, reducing guesswork and improving maintenance outcomes across the board.

Using the Right Vibration Tester

Choosing the right vibration tester machine depends on factors like the complexity of your machinery, the frequency of monitoring, and the skill level of your maintenance team. Higher-end models with advanced analytics capabilities can offer deeper insights, while simpler handheld testers may suit smaller operations. Some branded vibration testers also integrate with asset management systems, providing centralized data access and more comprehensive reporting. While initial investment can vary, the long-term benefits of preventing downtime and extending equipment life far outweigh the cost.

Organizations that prioritize equipment monitoring through vibration testing gain a competitive advantage in efficiency, reliability, and safety. Whether applied in manufacturing, utilities, automotive, or aerospace, vibration tester machines provide a clear view of machine conditions that empower maintenance teams to act with confidence. From early fault detection to reduced downtime and better planning, the value of a well-implemented vibration testing program is clear across all operational levels.